IMI’s Quality Control Solution

Why choose the quality control solution from IMI?

GET CONTROL

It allows you to adopt a proactive business approach by setting customized triggers against any possible non-compliance issues.

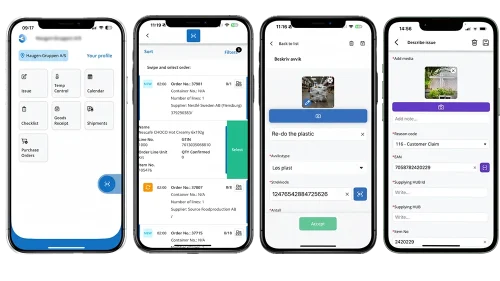

USER-FRIENDLY INTERFACE

Its user-friendly interface makes deviation handling easy and follow up

EDITABLE CATEGORIES

Its easy to create and edit any kind of groups and assign tasks.

Experience fast, easy and automated issue management

Discover the quality control solution from IMI

Some of the brands relying on IMI

IMI Supply Chain Solutions